Epilog 50W Mini

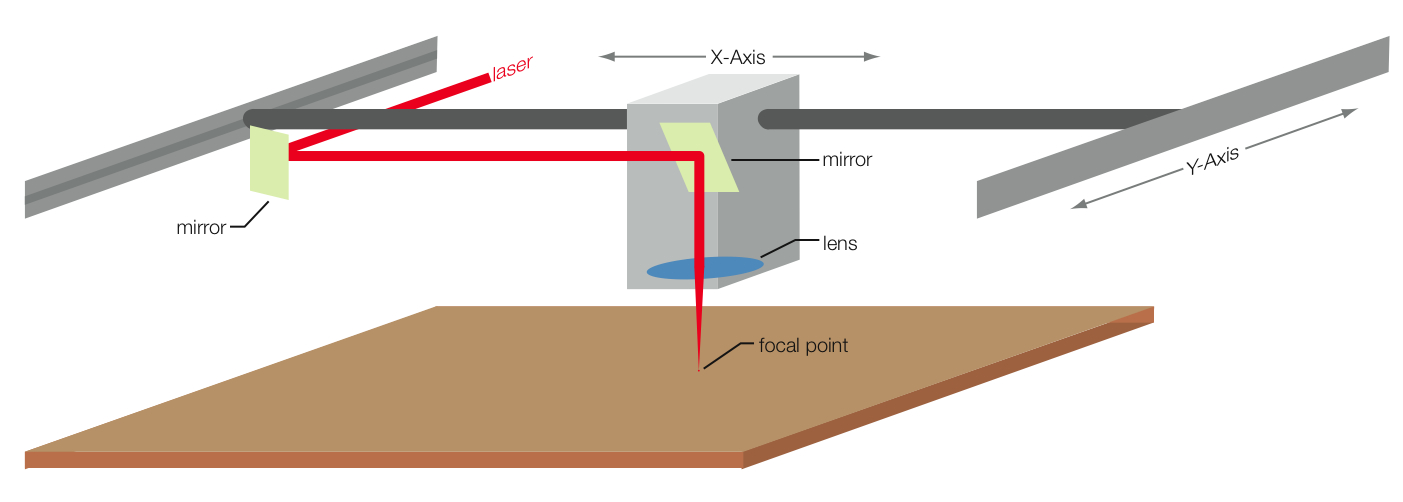

Diagram

This is a basic diagram of how the laser cutter works:

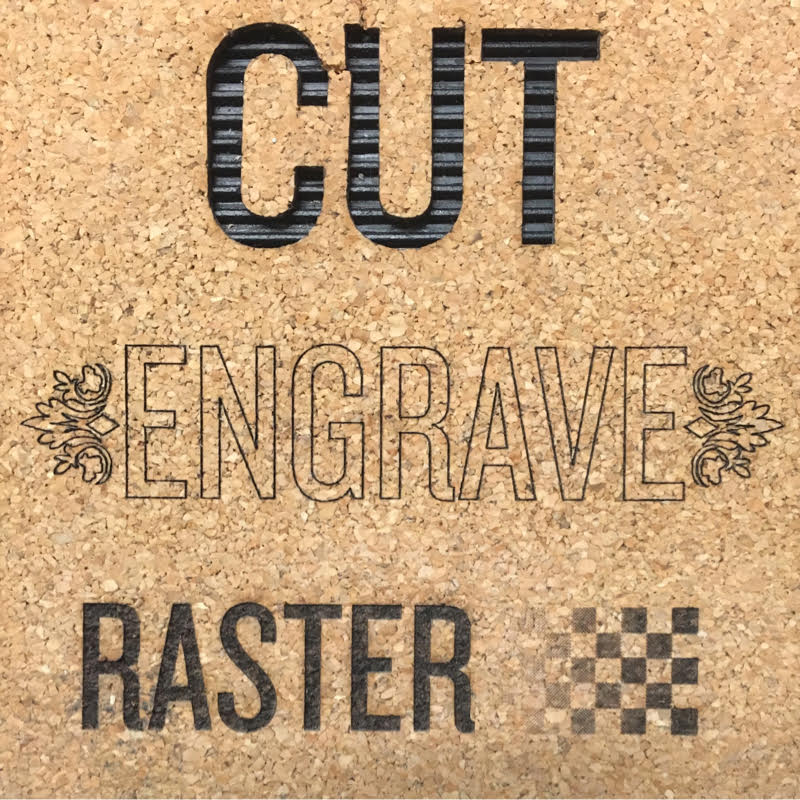

3 ways to Process Material

Vector Cut:

Vector lines cut all the way through a material, and are drawn as red lines (R=255, G=0, B=0).

Vector Engrave:

Vector lines that cut slightly into the surface of the material. It can be used to create text, graphics, or even texture on the surface of a material. Drawn as blue lines (R=0, G=0, B=255).

Raster:

Dot Matrix engraving of a hatch or pixelated image onto the surface of the material using variable intensity. This allows a black and white image to be created, where 100% black translates to 100% laser intensity, and 0% black translates to 0% intensity. Left as solid hatches/fills or images and best set to grayscale.

Since the machine has a Z-axis, you can specify how deep you want a path to be cut into the material. This is great for making dados or engraving graphics.

FAQs & Fun Facts

Making things fit together (Tolerance)

- If you are cutting out parts using the laser cutter, getting them to line up/fit snug together/make perfect angles is tough. Here are some things to think about when designing a part.

Plastics

- The diameter of the laser is about 1/100 inch, however some plastic will melt in the process of cutting (some cuts will appear wider than 1/100 inch as a result). Color can be a factor: because of the nature of light, white acrylic takes longer to cut than black acrylic (this is because white reflects a good amount of light from the laser while black absorbs most of it– the more a material absorbs, the hotter it gets). For most applications these things won’t matter, but if a tolerance of above 1/16 inch is necessary, you should ask for a test cut with your material to make sure things go as planned.

VINYL & PVC WILL CREATE CHLORINE GASS WHICH WAS USED IN WWI AS A CHEMICAL WEAPON!

Laser Drag and Material Thickness

- The laser doesn’t cut through a material instantly. It takes a few milliseconds to get through a piece. The thicker the piece, the longer it will take. There is an effect called drag which can be seen on most laser cut pieces: since the top of the material gets cut first, the laser will spend more time cutting the top, producing a slight slope on the side of the piece. It is impossible to account for with the laser, so some hand-finishing may be required if a perfect 90 degree angle is desired.

- The slope will be more extreme with a thicker piece of material. For this reason we usually do not cut anything thicker than 3/8 inch (although it is possible and you should still inquire about it).

- drag is very common on the Epilog Mini 50W especially with thin paper adjacent materials.

Slots and Tabs (are tricky)

- If your parts are designed to be assembled using a slot/tab system, make a few test cuts first. Common problems with slots/tabs:

- Shearing - If your slots and tabs are the exact same width and you try to jam two pieces together, they might snap. Especially if they are made of acrylic.

- Material variance - Every sheet of plywood/acrylic/cardboard/etc. is slightly different. A perfect set of slots and tabs on one sheet might not translate well on another sheet. When possible, run test cuts on the same sheet(s) you’ll be using for your parts.

- Drag - Sloping sides can affect how well two pieces fit together. It is essential to do test cuts for thick materials (larger than 1/4 inch).

Living Hinges

- I have a small library of living hinges, please see me for more info.

File Preparation Checklist

Use Template

Units: inches

Within X and Y bounds for machine

Within Z bounds, usually 0”-6” cutter depending.

Join Vectors.

Check for duplicate lines.

Create Layers.

Assign Vectors to colors and set strokes to .001

Print

Set preset to LC, click settings

Choose preferences

Select Advanced and load material settings

Layer Naming Convention

- CUT (Red)

- ENGRAVE (Blue)

- RASTER (Black)

Machine Preparation Checklist

Never clean any optic right after engraving or cutting because the optic may be hot and the cool lens cleaning solution may thermally shock the optic and crack it.

Air assist and Exhaust on

Set focus

Set origin

Tape or weigh lightweight material down

Guides & Documents

None as I haven’t been around one in a while and the only copy I ever got was paper. Looks like docs are not quick to find, but I only spent 15 sec.

Weekly Checklist

Clean X-Axis and Y-Axis bearings

Clean X-Axis and Y-Axis and bearing tracks

Clean X-Axis belt

Clean debris from under bed.

Notes

-

Can potentially use VISICUT to send files direct from student laptops.