3D printers

Learning Resources

Below is my basic info on FDM printing. A lot of my pedagogical practice is focused on 3D CAD modeling as evident on my Youtube. link

FDM Printers

How FDM 3D Printing Works.

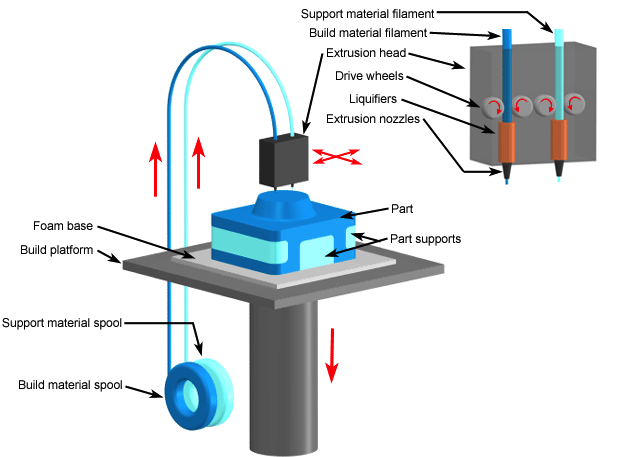

For this example we’ll use a Dimension ___ , manufactured by Stratasys. It is a Fused-Deposition Modeling system, and this is how it works: After a 3D model has been designed and exported to an STL, a special program slices it up into cross-sections thick. It looks at each cross-section and generates a set of instructions on how to build it. When this information is sent to the printer, it starts with the bottom-most layer, laying down plastic in the shape of the cross-section. When it finishes the first layer, it moves up a slice to start on the next layer. Take a close look at a 3D-printed model and you’ll notice that it is actually stepped. The machine consists of a moving bed (Z-axis) and a print head (X-axis and Y-axis). The print head has a heating element in it; thermoplastic is forced into the print head, melts, and is squeezed out, not unlike toothpaste. The print head is calibrated in such a way that the molten plastic coming out of it is almost always the same thickness. In order to form complex shapes, overhangs, and hinges/joints/free-moving objects, the plastic needs to be held up by something. The machine prints using a second material, which we call the ‘support.’ When the print is done, it is put in a bath of solution that dissolves away the support material, leaving only the finished model. Some machines do not have a second support material an instead have supports generated in the model material when sliced.

Dimension

The Dimension SST 1200es I operated at UArts was a lemon. Material was the main culprit, but it was also an abused machine before I got to operate it. The 170 is okay, but when you print you’re literally burning money.

Ultimaker

2+ Connect

Quite a good machine. From my own experience with various printers, this is the buy. I’d get one for myself if I needed one! The only issues I started running into were problems with the bowden tube after 100’s of hours of prints. Updated clips and more tubing were needed. This machine was my “express lane” printer that students could utilize if iterating on a design. Which meant it was proven printable on a Lulzbot w/o issue it could also offer quality comperable to the Dimension.

Lulzbot

Overview

Great printers.

- Lead Screws Lubricated (December 2019)

- Need firmware updates.

- Material Sample Test for Tolerance

- Benchy off of each printer

Printer Quirks @ NVD

Printer 1

- Y Belt Issues

- Has some nozzle contact issues on calibration.

- Needs new PEI.

Tolerances for 1x1x1 cube test: X Y Z

Printer 2

- Y Belt Issues

- Has some nozzle contact issues on calibration.

- Needs new PEI.

Tolerances for 1x1x1 cube test: X Y Z

Printer 3

- Y Belt Issues

- Has some nozzle contact issues on calibration.

- Needs new PEI.

Tolerances for 1x1x1 cube test: X Y Z

Printer 4

- Y Belt Issues

- Has some nozzle contact issues on calibration.

- Needs new PEI.

Tolerances for 1x1x1 cube test: X Y Z

Monoprice Maker Mini V2

Decent printer that I use at home directly off my PC with CURA. May set up Octoprint once I have a good location for the printer.

Monoprice Maker Select

Run away from these fire-hazards. Even after fixing the thermistor…

Makerbot

Replicator

Solid machine, likes loose extrusion, hard to keep consistent temp. Once it gets gremlins they stay.

Replicator 2

Horrible machine, all I have interacted with have had ribbon cable gremlins. Run away.

Replicator 2X

Really decent when they work. Can be very temper-mental. Does two materials well.

Plastic Recycling Research

- Recycle Bot

- Precious Plastics

Materials Review

- NGEN is great, but fractures, super shiny.

- PLA, good-old standard. Watch for moisture and dust.

- ABS, only for enclosed dimension, very susceptible to moisture damage.

- Ninjaflex, only used once. Can’t use at home.

- TPU, want to try.

SLA Printing

Form 2?

Super interesting printer, not student friendly. I spent 2 months servicing one that a student almost broke the year before I got to NVD. Definitely get a good UV box or clean sunny space. There is actually a horrible design flaw in the spring connectors between the printer and the resin basin…

- Inventory Material

- Write up checklist for proper handling

Shapeways Printing

Sandstone Printing

Done through shape-ways, link image from minecraft!

Ceramic Printing

Done through shape-ways, link image from Ryans gift!

Notes that need to get added into above or gcode…

-

[ ]Where is my intro to printing materials?

-

[ ]Working with Tolerance and Support Material.

-

[ ]There are a few basic guidelines to follow when developing a model for printing. These won’t help you edit a model; these are things to keep in mind when designing it.

-

- [ ]Wall Thickness - The printer can print walls as thin as ~0.01”, however these will not be structurally sound. Keep walls to a minimum of 0.04” for rigid structure.

-

- [ ]Suspended Parts - It is possible to make joints by leaving some space between two interlocking parts; leave at least 0.02” or the printer may connect the two parts. If a part is threaded or must fit snugly, it is best to print it separately (when possible).

-

[ ]Model Interior settings:

-

- [ ]Solid: fills any interior space with 100% plastic. Strongest and most expensive option.

-

- [ ]Sparse High Density: fills interior space with a grid pattern. Very strong and cheaper than Solid fill.

-

- [ ]Sparse Low Density: fills interior space with a grid pattern using less plastic than Sparse High Density. Uses the least plastic and is therefore the cheapest.

-

[ ]Support Fill settings:

-

- [ ]Minimal: uses the least amount of material and is therefore the cheapest option.

-

- [ ]Sparse: uses more material than Minimal. Only necessary when printing complex overhangs or objects that require a high tolerance.